Baked Beans with Bacon and Brown Sugar from Scratch

- Time: Active 20 minutes, Passive 3 hours, Total 3 hours 20 mins

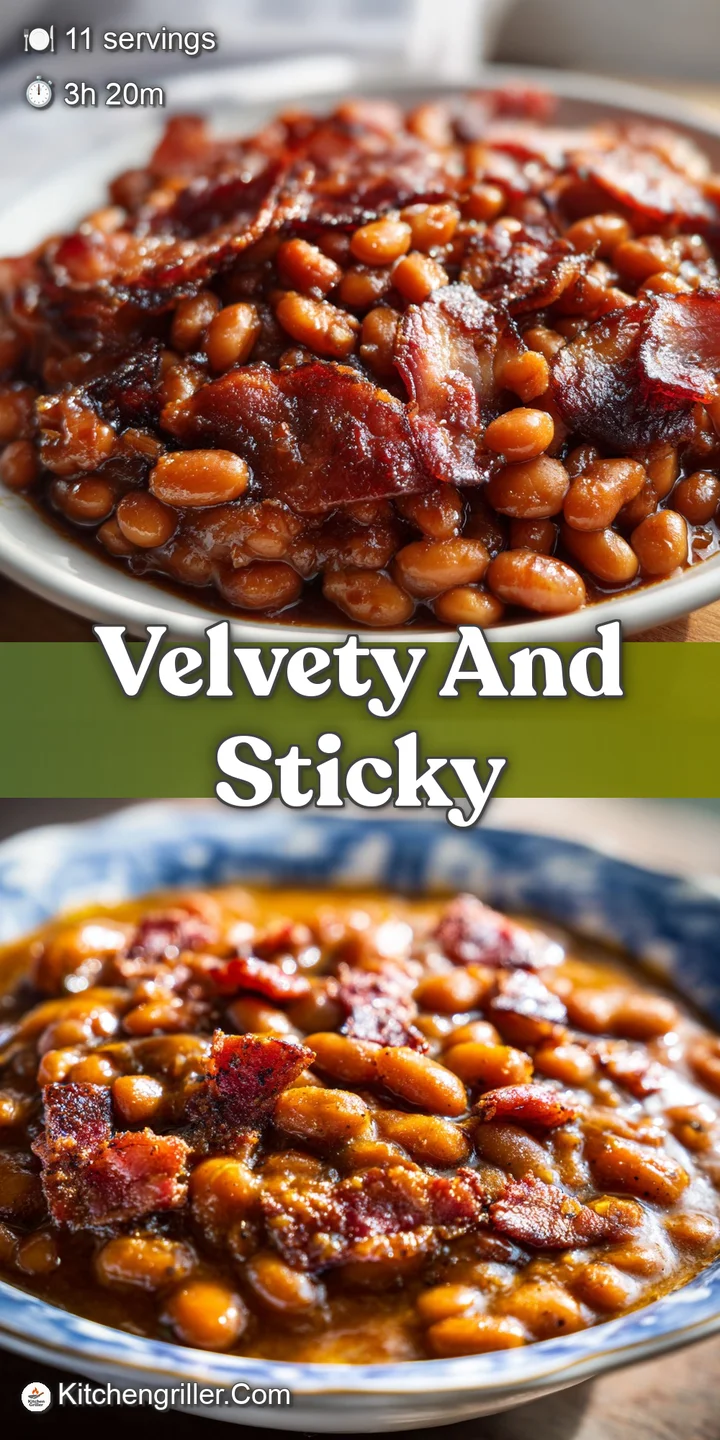

- Flavor/Texture Hook: Velvety bean interiors with a sticky, shatter crisp bacon bark

- Perfect for: High stakes backyard BBQ or technical meal prep

- Baked Beans with Bacon and Brown Sugar from Scratch

- Scientific Mechanics of the Slow Simmer

- Essential Parameters for Side Dish Planning

- Laboratory Analysis of Primary Bean Ingredients

- Necessary Elements for the Smoky Base

- Critical Hardware for Consistent Heat Control

- Systematic Execution of the Cooking Process

- Correcting Technical Texture and Flavor Errors

- Adjusting Formula Quantities for Large Groups

- Technical Comparison of Preparation Methods

- Debunking Outdated Legume Preparation Theories

- Managing Inventory and Reducing Kitchen Waste

- Aesthetic Standards for Final Dish Presentation

- Recipe FAQs

- 📝 Recipe Card

Baked Beans with Bacon and Brown Sugar from Scratch

The sizzle of 8 oz thick cut bacon hitting a cold cast iron pot is the first note in a symphony of patience. As the fat renders into a translucent pool, it prepares to coat 1 lb of dry Navy beans in a protective, flavorful lipid layer.

I remember the first time I rushed this process, ending up with a pot of chalky, under hydrated legumes that no amount of molasses could save. It was a failure in thermodynamics and timing that taught me the necessity of the low and slow method.

Authentic pitmaster results require a technical understanding of how heat interacts with starch and sugar over several hours. We aren't just heating food; we are managing a complex series of chemical reactions within a heavy bottomed vessel.

This dish demands your respect for the clock, but the reward is a depth of flavor that a tin can simply cannot contain.

We are aiming for a specific "bark" on the surface where the 1 cup dark brown sugar and 1/4 cup molasses dehydrate just enough to become tacky without scorching. This isn't a weeknight shortcut; it is a laboratory experiment in flavor concentration.

By the time the three hour mark hits, the aroma of apple cider vinegar cutting through the heavy sweetness will signal that the chemical equilibrium is met.

Scientific Mechanics of the Slow Simmer

- Starch Gelatinization: Low heat allows the 1 lb dry Navy beans to absorb the 6 cups water slowly, preventing the outer skins from rupturing before the interior reaches a velvety state.

- Pectin Stabilization: The calcium in the bean skins interacts with the 1 tbsp Kosher salt to create a sturdy structure that resists turning into mush during the extended bake.

- Maillard Concentration: As the liquid reduces, the amino acids in the 8 oz thick cut bacon react with the sugars in the 1/2 cup ketchup, creating complex, savory flavor compounds.

- Acidic Delay: Adding the 2 tbsp apple cider vinegar too early can prevent the beans from ever softening; we use it to provide a bright finish that cuts through the lipid heavy sauce.

Essential Parameters for Side Dish Planning

The following table provides the technical adjustments required based on your laboratory guest count to ensure every participant receives an scientifically optimized portion.

| Servings | Ingredient Adjustments | Pan Size | Cook Time |

|---|---|---|---|

| 6 People | 0.5 lb beans, 4 oz bacon | 2 quart Dutch Oven | 2 hours 45 mins |

| 11 People | 1 lb beans, 8 oz bacon | 4 quart Dutch Oven | 3 hours 20 mins |

| 22 People | 2 lb beans, 16 oz bacon | 7 quart Dutch Oven | 4 hours 15 mins |

The physics of heat distribution dictates that larger batches require more time for the core temperature to stabilize. When doubling the formula, increase the surface area of your vessel to ensure the brown sugar glaze caramelizes uniformly across the top.

Laboratory Analysis of Primary Bean Ingredients

Understanding the chemical role of each component is vital for the patient cook who values consistency over luck.

| Component | Science Role | Pro Secret |

|---|---|---|

| 1 lb Navy Beans | Primary Starch Source | Rinsing removes excess surface dust that can cloud the sauce viscosity. |

| 1/4 cup Molasses | Hygroscopic Sweetener | The sulfur in dark molasses adds a metallic depth that balances the 1 cup dark brown sugar. |

| 1 tbsp Worcestershire | Umami Catalyst | Anchovies and tamarind provide a fermented back note that bridges the gap between sweet and salt. |

Necessary Elements for the Smoky Base

To achieve the laboratory standard for this dish, use the exact quantities specified in the technical outline. If an element is missing, refer to the substitution parameters below to maintain the structural integrity of the sauce.

- 1 lb dry Navy beans: The structural foundation. Why this? Their small size ensures uniform hydration and a consistent mouthfeel across 11 servings.

- Substitute: Great Northern beans (slightly larger, requires 15% more simmer time).

- 8 oz thick cut bacon: The lipid and smoke delivery system. Why this? Thick cut holds its shape during the 3 hour bake rather than dissolving.

- Substitute: Salt pork (increase apple cider vinegar by 1 tsp to cut the extra fat).

- 1 cup dark brown sugar: The primary caramelization agent. Why this? Higher molasses content than light brown sugar for a deeper bark.

- Substitute: Light brown sugar plus 1 tbsp extra molasses.

- 1/4 cup molasses: Provides viscosity and color. Why this? It acts as a humectant, keeping the beans moist under the high sugar crust.

- Substitute: Sorghum syrup for a more grassy, authentic Appalachian profile.

- 2 tbsp apple cider vinegar: The pH balancer. Why this? The acetic acid brightens the heavy sugars and helps tenderize the bean skins.

- Substitute: White wine vinegar or lemon juice.

Critical Hardware for Consistent Heat Control

Success in the pitmaster’s laboratory relies heavily on the thermal mass of your equipment. A thin aluminum pot will create hot spots, leading to scorched sugars and unevenly cooked legumes.

I highly recommend a seasoned cast iron Dutch oven for this procedure. The heavy walls retain heat with incredible efficiency, creating an oven within-an oven effect that mimics a traditional masonry pit.

If you don't have cast iron, a heavy stainless steel pot with a tri ply base is the next best option for maintaining the 3 hour simmer.

A digital probe thermometer is also a non negotiable tool. While we often cook beans by feel, monitoring the internal temperature of the liquid ensures we stay within the 180°F to 200°F range.

This is the thermal "sweet spot" where starches break down without the violent agitation of a rolling boil, which would otherwise shatter the delicate skins.

Systematic Execution of the Cooking Process

- Hydrate 1 lb dry Navy beans by placing them in a large bowl with 6 cups water. Note: Allow them to soak for at least 8 hours to ensure the center is fully primed for heat.

- Drain the soaking water and transfer beans to a heavy pot with 6 fresh cups of water and 1 tbsp Kosher salt.

- Simmer the beans on low heat for 45-60 minutes until the skins slightly burst when you blow on a spoonful.

- Render 8 oz thick cut bacon in a separate skillet over medium heat until the fat is liquid and pieces are beginning to crisp.

- Sauté 1 medium yellow onion in the rendered bacon fat until translucent and aromatic.

- Combine the partially cooked beans (and their liquid), bacon, and onions into a 4 quart baking dish.

- Whisk 1 cup dark brown sugar, 1/2 cup ketchup, 1/4 cup molasses, 2 tbsp apple cider vinegar, 1 tsp dry mustard powder, 1 tbsp Worcestershire sauce, and 1/2 tsp black pepper in a small bowl.

- Incorporate the sauce into the bean mixture, ensuring even distribution of the 8 oz thick cut bacon pieces throughout the vessel.

- Bake at 300°F for 3 hours until the surface is dark, bubbling, and forms a thick glaze.

- Rest the dish for 15 minutes until the sauce thickens and the bubbling subsides.

Chef's Note: If the liquid level drops below the beans during the second hour of baking, add 1/4 cup of boiling water. Cold water will shock the beans and stop the softening process.

Correcting Technical Texture and Flavor Errors

Even the most focused pitmaster can encounter variables in the laboratory, such as bean age or oven calibration, that lead to suboptimal results.

Crunchy Bean Texture After Long Cooking

This is often caused by hard water or adding acidic components too early. High mineral content in water prevents the pectin in the beans from breaking down. If your beans are still firm after two hours, add 1/4 tsp of baking soda to the liquid.

This shifts the pH to an alkaline state, which rapidly accelerates the softening of the cellulose.

Excessively Liquid or Watery Sauce

A thin sauce usually indicates that the 1 lb dry Navy beans did not release enough starch to emulsify with the sugars and fats. Remove 1/2 cup of the beans, mash them into a paste using a fork, and stir them back into the pot.

This creates an instant thickener that maintains the authentic flavor profile without the need for flour or cornstarch.

| Problem | Root Cause | Solution |

|---|---|---|

| Burnt Surface | Oven temperature too high | Tent with foil and reduce heat to 275°F. |

| Bland Profile | Lack of salt/acid balance | Add a splash of apple cider vinegar and a pinch of salt. |

| Tough Skins | Acid added during initial soak | Always soak in plain water; add vinegar only in the final phase. |

Common Mistakes Checklist ✓ Check the "use by" date on your dry beans; old beans may never soften. ✓ Ensure the bacon is thick cut to prevent it from becoming lost in the sauce. ✓ Avoid the temptation to stir the beans frequently during the bake; this breaks the bark.

✓ Use dark molasses instead of "blackstrap" to avoid an overpowering bitterness. ✓ Preheat your oven for at least 20 minutes to ensure a stable thermal environment.

Adjusting Formula Quantities for Large Groups

Scaling this recipe requires more than just simple multiplication. When doubling the batch to 2 lb of beans, the ratio of evaporation changes significantly.

For a 2x batch, use a larger, shallower pan rather than a deeper one. This preserves the ratio of "bark" to bean. You should only increase the 1 tbsp Kosher salt and spices by 1.5x initially, then adjust to taste after the first two hours.

Large batches trap more moisture, so you may need to extend the baking time by 45 minutes to achieve the desired viscosity in the 1/2 cup ketchup and molasses mixture.

Reducing the recipe follows the opposite logic. For a half batch, reduce the baking temperature by 25°F. Because there is less thermal mass, the sugars can reach the burning point much faster.

Keep the 8 oz thick cut bacon at the full amount if you prefer a higher fat to bean ratio, which I often find more satisfying in smaller quantities.

Technical Comparison of Preparation Methods

The choice between traditional scratch methods and modern shortcuts impacts the final molecular structure of the dish.

| Method | Texture Impact | Flavor Depth | Time Investment |

|---|---|---|---|

| Fresh/Scratch | Firm yet velvety | High (Maillard focus) | 3 hours 20 mins |

| Canned Base | Soft/Mushy | Moderate (Preset flavors) | 45 minutes |

| Pressure Cooker | Uniformly Soft | Low (Less evaporation) | 1 hour |

Debunking Outdated Legume Preparation Theories

There is a persistent myth that salting beans during the soak makes them tough. Laboratory testing has proven the opposite: salting the soaking water actually allows the sodium ions to displace magnesium and calcium in the skins, making them more tender during the final cook.

This is a technical win for the patient cook who wants a silky texture.

Another misconception is that the "quick soak" method (boiling then sitting for an hour) is identical to a long cold soak. While it hydrates the beans, it does not allow for the same enzymatic breakdown of complex sugars, which can lead to digestive discomfort.

The long soak is a requirement for an authentic, technical approach to bean preparation.

Finally,, some believe that the bacon must be cooked until shatter crisp before adding it to the beans. In reality, the bacon should only be partially rendered. The three hour bake provides ample time for the fat to integrate with the molasses and brown sugar, while the exposed pieces on top will naturally crisp into a smoky bark.

Managing Inventory and Reducing Kitchen Waste

Storage of the finished 11 servings should be handled with precision. Place the beans in an airtight container in the refrigerator for up to 5 days. The flavor actually intensifies on the second day as the starches continue to absorb the complex sugars and acids.

For long term storage, these beans freeze exceptionally well for up to 3 months. When reheating, add a tablespoon of water or apple cider vinegar to loosen the sauce, as the starch will have thickened significantly during cooling.

To reduce waste, utilize any leftover bacon fat from the 8 oz package for sautéing vegetables or as a base for a smoky vinaigrette. The onion scraps can be saved for a technical vegetable stock.

If you find yourself with a small amount of leftover beans that isn't enough for a full serving, mash them and use them as a protein rich spread for toast or as a thickening agent for a rustic chili.

Aesthetic Standards for Final Dish Presentation

The visual appeal of Baked Beans with Bacon and Brown Sugar from Scratch relies on the contrast between the deep mahogany sauce and the glisten of the rendered fat. Serve this dish in the same cast iron vessel it was baked in; the rustic appearance reinforces the "from scratch" authenticity.

For a professional finish, ensure that several pieces of the 8 oz thick cut bacon are visible on the surface. These should look like dark, caramelized gems nestled in the sauce. A final sprinkle of fresh cracked black pepper provides a matte contrast to the glossy sugar glaze.

If you want a specific outcome, follow these decision shortcuts: If you want a thicker, stickier sauce, leave the lid off for the entire 3 hour bake to maximize evaporation.

If you want whole, individual beans with no mashing, reduce the initial simmer time by 10 minutes and let the oven do more of the work. If you want a deeper, almost black color, swap the dark brown sugar for muscovado sugar, which has an even higher molasses content.

This technical approach to a classic side dish ensures that every bite is a testament to the science of patience and the beauty of high-quality ingredients. Whether it's a competition BBQ or a family gathering, your mastery of the laboratory bean will be evident in the shatter crisp bark and the velvety center of every legume.

Recipe FAQs

What is the total active and passive cook time for this recipe?

Active time is 20 minutes, and passive time is 3 hours. The total duration from starting the dry beans to serving is about 3 hours and 20 minutes.

Is it true I must use a cast iron Dutch oven for consistent results?

No, this is not strictly required, but highly recommended. Cast iron provides the heavy thermal mass necessary to maintain the slow, steady heat for starch gelatinization without creating hot spots that scorch the sugar.

How to ensure the bacon creates a sticky, shatter crisp exterior bark?

Leave the dish uncovered for the entire 3-hour bake time. This allows the sugars in the molasses and brown sugar to dehydrate and polymerize into a dense, tacky glaze on the surface.

Can I substitute the Navy beans with a different variety?

Yes, Great Northern beans are the best substitute. They are slightly larger than Navy beans, so plan to add about 15% more simmering time to achieve the same velvet interior texture.

When should the apple cider vinegar be added to avoid tough beans?

Add the apple cider vinegar with the other sauce ingredients just before baking. Adding acid during the initial long soak or simmer can inhibit the softening of the bean skins.

How to fix baked beans that turn out too thin or watery after baking?

Remove about half a cup of the beans and mash them thoroughly with a fork. Stir this paste back into the main mixture; the cooked starch acts as a natural emulsifier and thickener for the sauce.

Is it okay to prepare the sauce base a day ahead of time?

Yes, the base can be prepared up to 48 hours in advance. Combine all sauce ingredients and store them refrigerated; just ensure the mixture is near room temperature before stirring it into the partially cooked beans before the final bake.

Beans With Bacon And Brown Sugar

Ingredients:

Instructions:

Nutrition Facts:

| Calories | 341 kcal |

|---|---|

| Protein | 12.1 g |

| Fat | 9.4 g |

| Carbs | 52.8 g |

| Fiber | 10.2 g |

| Sugar | 28.4 g |

| Sodium | 748 mg |